System Lift Dimensions Explained: Why They Issue for Lift Servicing

Wiki Article

Extensive Evaluation on Usual Issues and Solutions in Lift Repair

In the world of lift fixing, a meticulous evaluation of common concerns and their matching remedies is vital to making certain the smooth procedure and safety and security of these necessary upright transport systems. From the troublesome problems with elevator doors to the complex intricacies of electrical breakdowns, a myriad of obstacles can torment lift performance (lift repair). As we explore the ins and outs of elevator maintenance, a comprehensive understanding of these issues and the reliable strategies for solving them emerges as a critical facet of making sure optimum lift performanceLift Door Issues

Among the most usual challenges come across in lift upkeep is resolving lift door breakdowns. The smooth procedure of lift doors is vital for passenger security and effectiveness. A malfunctioning door can cause delays, trouble, and also possible risks.Elevator door issues can stem from numerous factors, such as faulty door sensors, misaligned doors, damaged rollers, or concerns with the door driver system. These breakdowns can result in doors not opening or shutting appropriately, obtaining stuck midway, or also shutting also swiftly, positioning a danger to travelers going into or leaving the lift.

To attend to elevator door breakdowns efficiently, maintenance service technicians need to carry out regular evaluations, lubricate relocating components, adjust door timings, and replace damaged components immediately. In addition, carrying out precautionary maintenance timetables can assist determine and resolve possible door problems prior to they intensify. By prioritizing elevator door maintenance and quickly addressing breakdowns, building proprietors can guarantee the secure and efficient procedure of their lifts.

Electrical Malfunctions

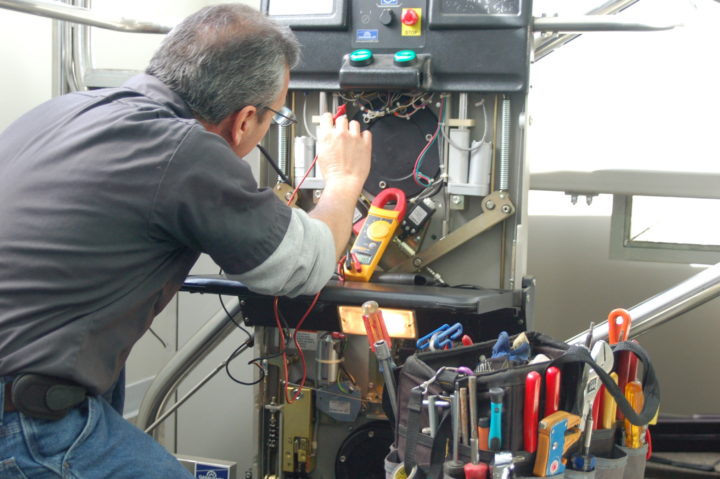

Resolving electric malfunctions in lifts calls for complete diagnostic assessments and exact troubleshooting methods to guarantee the reliable and secure performance of the elevator system. Electric malfunctions can materialize in numerous methods within a lift system, varying from issues with the control board, faulty electrical wiring, power supply issues, to problems with sensors and interlocks. When experiencing electric malfunctions, it is important for maintenance personnel to comply with a systematic technique. This includes checking the power supply to the lift, inspecting circuitry for any signs of damages or wear, and examining the capability of crucial elements such as the control board and emergency situation quit switch. Utilizing diagnostic devices such as multimeters and circuit testers can aid in pinpointing the source of the electric malfunction accurately. In addition, making certain that all electrical links are protected and up to code is vital in stopping future malfunctions. By attending to electric problems promptly and properly, lift technicians can preserve the safety and effectiveness of elevator operations.Hydraulic System Problems

In addition, hydraulic pump failings can occur because of issues such as getting too hot, extreme wear, or lack of proper upkeep. A malfunctioning pump can bring about the lift not having the ability to create adequate hydraulic pressure to run efficiently. Normal examination, upkeep, and prompt substitute of hydraulic parts can avoid these problems and ensure the smooth functioning of the lift system. Appropriate training for maintenance employees on hydraulic system fixing and fixing can likewise assist in resolving these issues quickly and successfully.

Control System Glitches

Control system breakdowns can disrupt the smooth procedure of lift systems and present safety and security risks if not quickly dealt with. These glitches commonly originate from issues such as electric failings, software application pests, or sensor malfunctions. When the control system stops working to communicate effectively with the lift elements, it can lead to unpredictable activities, unanticipated quits, or full closures. One typical problem is the misalignment of sensing units, resulting in unreliable floor leveling and door procedures. Electric failings, consisting of power rises or damaged electrical wiring, can additionally create the control system to malfunction.To resolve control system glitches, lift repair technicians need to additional reading conduct comprehensive diagnostics to determine the root reason of the issue. This might include examining the electrical links, calibrating sensing units, or reprogramming the control software. Normal upkeep checks can aid stop these problems by determining possible concerns before they intensify (lift breakdown). By immediately addressing control system breakdowns, lift operators can make sure the safety and dependability of their systems for guests and prevent pricey downtime.

Safety And Security Includes Concerns

In making certain the optimal functionality of lift systems, caution in the direction of the stability of safety functions ends up being extremely important adhering to the identification and resolution of control system problems. Safety and security features in lifts are designed to avoid mishaps, malfunctions, and injuries. Attending to safety feature worries immediately can substantially reduce the risk of crashes and enhance the total safety of lift operations.Final Thought

Finally, common concerns in lift fixing include elevator door concerns, electric breakdowns, hydraulic system troubles, control system glitches, and safety functions worries. It is important for upkeep groups to attend to these problems immediately to ensure the efficient and safe procedure of elevators. By implementing appropriate maintenance methods and normal inspections, these concerns can be determined and dealt with successfully to avoid any type of disruptions in lift feature.

In making sure the optimum functionality of lift systems, vigilance in the direction of the stability of safety features ends up being extremely site here important following the recognition and resolution of control system glitches - lift servicing companies.In verdict, typical problems in lift repair work consist of lift door problems, electrical malfunctions, hydraulic system troubles, control system problems, and security functions issues

Report this wiki page